Hellooooooo!

I’m back today with the most-requested project from my living room makeover—the DIY storage coffee table!

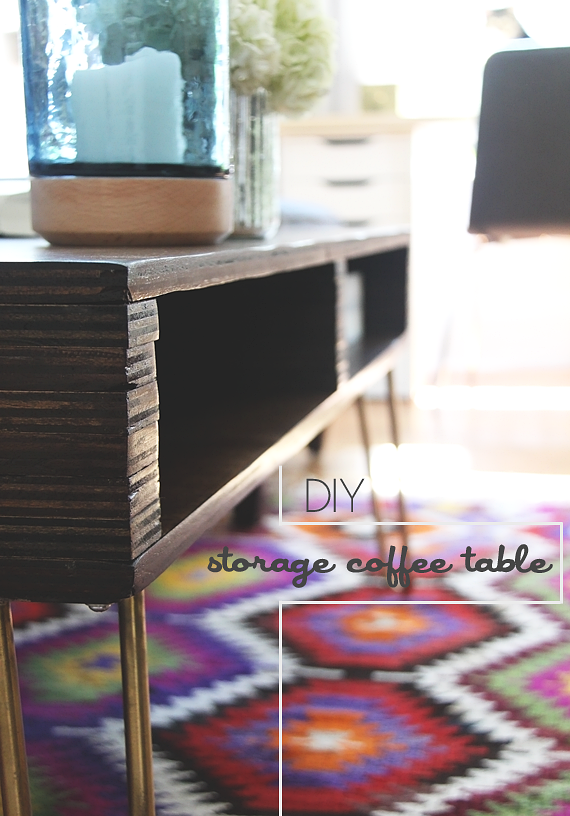

We’ve been living with this table for a few weeks now and I have to say…we love it. It provides the perfect amount of storage for our needs without looking bulky, and the stained birch plywood and brass hairpin legs are YUMMY.

Wood joining typically involves tools I only dream of owning, so when I started fantasizing about building my own custom coffee table, I was at a loss for how to create storage without taking an extensive course in woodworking.

Until I saw this fabulous stacked plywood media console by Homemade Modern. The technique is so genius and above all, EASY. With just a few changes, I was able to adapt the project to make a simple coffee table. BOOM!

Alright folks, roll up your sleeves; this DIY is easy to do, but involves a bunch of steps, so I’m gonna stop gabbing and get to the tutorial!

DIY Storage Coffee Table

Skill Level: Medium, but only because you need to know how to use a power drill; if you do, you’re golden!

Time: 1 week to sand, stain, and seal the wood; 1-2 hours to build the table

What You Need for One 18.5″ H x 22″ W x 48″ L Table:

- 1 sheet of 3/4″ birch plywood

- coarse, medium, and fine grit sandpapers

- a LOT of non-linting rags (old t-shirts work well)

- wood stain (I prefer the Minwax oil-based stain in dark walnut)

- clear sealant (my fav is Varathane Polyurethane in satin, as it can be applied over both oil or water-based stains, and you don’t need to sand between coats)

- foam brushes

- power drill (the Ryobi drill and driver combo kit is my baby!)

- 100-pack #8 x 1-1/4″ flat head wood screws

- wood glue

- 4 table legs—the 13″ brass hairpin legs I used were a totally worthwhile splurge from Reform Brass; there are also tons of options at Hairpin Legs for Less (as recommended by Emily Henderson!)

- wood screws that work with the legs you choose (in my case, #12 x 1″ round head)

What You Do:

Step One — Have your wood cut in the hardware store as follows:

- 2 pieces 22″ x 48″ for the top and bottom of the table

- 18 pieces 22″ x 2″ for the supporting braces (Go ahead and get a handful of extras; they’re ideal to test stain colors, and you’ll have some spares if the widths don’t come out perfect since your wood is being cut by humans and not robots).

Step Two — Sand, stain, and seal the wood (not pictured).

Is it lame of me to not show this part? Absolutely. Someday I hope to do my own tutorial on prepping wood, but for now, I will send you to this helpful video on staining and sealing wood. A few notes from my personal experience:

+ Since we’re working with raw plywood, you definitely need to sand thoroughly, starting with a coarse grit sandpaper and working through to a fine grit. And yes, power sanders are worth the money! Unless you like useless jelly arms.

+ You don’t need to use wood conditioner before staining!

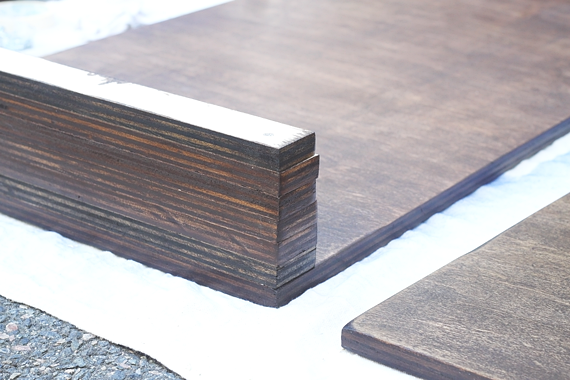

+ Save yourself some time by only staining and sealing the edges of the braces—that’s why mine are all naked in the middle.

+ I like applying the sealant with a cheapo foam brush—it’s super easy and doesn’t leave brush marks.

………………………………………

Before putting everything together, let’s take a minute to visualize the construction of the coffee table. The table will be assembled upside-down, so that the screws don’t end up showing on the top of the table.

Below you can see the TOP piece in the back, good side facing down, with the braces arranged in three stacks of 6. The front piece in the picture is the BOTTOM of the table, good side facing up. Capiche?

………………………………………

Step Three — Now to actually start assembly. Grab your first brace piece to attach to the underside of the top of the table (in other words, the good side is still facedown). Smear a couple dabs of wood glue on the brace piece.

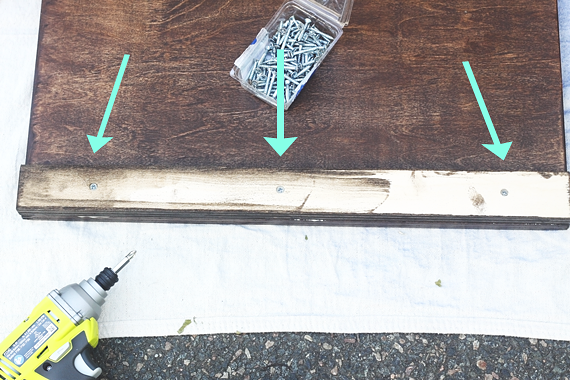

Step Four — Line the brace up to the edge of the table, glue side down, and drive in 3 screws to secure the brace. Wipe away any excess glue before it dries.

Step Five — Apply glue to the second brace, place it on top of the first, and screw it down—alternating the placement of the screws so they don’t run into the first ones. As indicated by these totally professional arrows in the photos.

Step Six — Repeat Steps 3-5 until you have attached 6 braces to the end of the table. Just remember to keep alternating the screw placement and wiping off excess glue!

Step Seven — Attach the rest of the braces to the middle and other end of the table. This will prevent the middle of the table from bowing over time, AND makes two handy storage cubbies.

………………………………………

Let’s check in to visualize again. I’m a very visual learner so naturally I’m assuming you are too. On the left we have the TOP of the table, facing down with the braces all snugly attached. On the right is the BOTTOM of the table, facing up.

………………………………………

Step Eight — Flip the BOTTOM piece over onto the rest of the table.

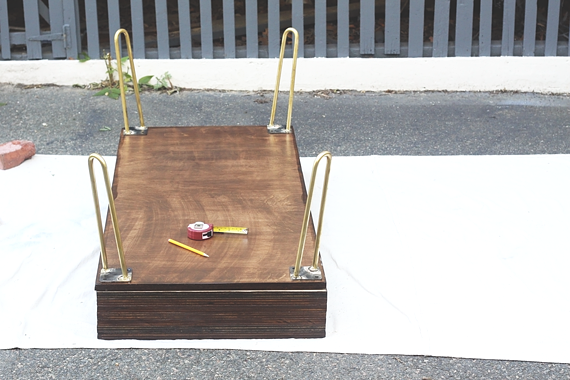

Step Nine — Place the legs onto the table and mark where they will be attached with a pencil—but don’t attach them yet, this is just so you know where not to drill in the next step.

Step Ten — Attach the bottom of the table using wood glue and screws just like you did with the braces. It can be helpful to have a friend (or FIANCEÉ) hold it in place for you. Drive the screws into the end and middle braces so the table is firmly attached along the whole piece (just don’t drill where the marks for the legs are).

Step Eleven — Finally, attach those legs.

And you’re done!

Bring that baby inside and stash away your remotes and coasters and coffee table books and whatever else you like to keep handy.

Bet you didn’t think building a fabulous custom piece of furniture could be so easy, eh?

The great thing about this technique is you could totally adapt it to other types of furniture. Desks! Nightstands! Hallway benches! So many possibilities!

Just be careful—building furniture is highly addictive. I want to learn all the skills and build all the things!

Guess my dad’s Master Cabinetmaker genes are finally switching on.

simply marvelous! i wish i had a handy-man so i could get him to craft everything i need found on line! lol! great job girl. pinned ;D

Oh lady, be your own handy-(wo)man! You can do it! 🙂

UGH, YES, this is so so so so so so good. I was wondering how you got that amazing texture on the sides- stacked plywood!!! Amazing, and wayyy simpler than expected. Beautiful work <3

Thank you thank you friend! I looooove the texture too, turned out way cooler than I expected. 🙂 xoxo

Love it! I may be considering this when I focus my attentions on my living room soon. Also, I spy a familiar pair of scrubs in the corner of one picture 🙂

Haha, yes! The ubiquitous scrubs! You should totally do it—it’s so easy! xoxo

Brilliant! And it looks fantastic! Great job you 🙂

XOXO

Yay, thank you! Hugs!

Say whaaa, this is AMAZING! I had no idea it was handmade when I saw your living room reveal. ::insert clapping emoji here::

Ooo, that’s the best compliment of a DIY project! 🙂 Thank you Rachel! ::insert bowing emoji::

Yes! This is incredible!

Aww, thank you Caitlin! You ladies make some seriously amazing wood projects, so that is high praise! 😀

Brilliant!!

Why thank you!!

WOW! This is gorgeous. It looks straight out of Anthro! I want to make an end of the bed version 🙂

Mission accomplished! I seriously told my fiancee about this comment, THANK YOU! 🙂 And yes, this would be phenomenal as a nightstand! I would love to see it!

WOW! I love this… Doesn’t look DIY – so legit.

Thank you thank you! 😀

is it sturdy enough with the hairpin legs? I have see a couple table and bench diy’s and wonder how sturdy it is! Like how much weight could it hold, is it wobbly, etc. ?

Hi Amanda, thanks for this great question! The table is very sturdy—these particular hairpin legs are super thick and can be used to support a bed frame according to their maker. If you’re doing your own bench/table project, I would just see if the hairpin legs you want to use have a weight rating and go by that. For a bench, I would maybe suggest using a solid wood (try framing lumber, it’s cheap but wicked sturdy). I just found a project on Lowe’s that uses pretty thin but solid wood for benches: http://www.lowes.com/creative-ideas/woodworking-and-crafts/pipe-frame-harvest-table/project#noop. The table I made is a teensy tiny bit wobbly, but that is only because when attaching one of the legs I stripped a screw hole and so that spot wiggles a bit. I’ve been meaning to fix it but you know what they say about good intentions… Anyways, hope that helps! 🙂

Hi! love your table here.

Question – did you sand the sides of the braces, or just sand the table top/bottom?

Thanks!

Thanks so much for visiting, and so sorry for the late reply! Yes, I did lightly/briefly sand the sides of the braces. Sanding the wood helps stain to adhere better, so always do what you can!

Let me know if you have any more questions!

xoxo

This is such a gorgeous table! I love it!

Thank you thank you Bre! xoxo

This is excellent! I’m curious… approximately how much did the materials cost?

Thank you, glad you liked it! I think the cost for this project varies widly on what materials you use. For example, pine plywood is cheaper than birch plywood, and I purchased super fancy solid brass hairpin legs, but there are many less expensive models on the market. I paid around $150 for everything, but again, you can get away with less! Let me know if you have any other questions! xoxo

What color spray paint did you use for your legs?

Hi Kelsey,

These are actually solid brass hairpin legs! If you want to save some dough and spray cheaper legs, then my favorite gold/brass spray paint is Rustoleum Metallic in gold. Good luck!

Hi! I am dying to know where this rug is from! Thanks!

Hi! The rug was from Kaya Kilims — she has AMAZING rugs! https://store.kayakilims.com/